Description

we has exhaustive quality control and assessment procedure which takes care that only products that are defect-free and conforms to the set guidelines by respected international agencies. We are a manufacturer, supplier, and exporter of Equal Tees which are also known as ‘straight tees’. These tees have a diameter that is similar to the diameter of the main pipe, hence the name ‘equal tee’. We furnish SS Butt weld Equal Tees that are installed without much hassle and require less maintenance as well. Being corrosion

resistant and give a quick disconnection in case of emergency. We export large quantities of ANSI B16.9 Equal Tees to industries like power plants, breweries, sugar, etc

The company manufactures, supplies and distributes a wide range of fittings, such as elbows, tees, reducers, caps, bends and many others from 1/2″ to 120″ diameter in all material grades, according to international standards and clients’ requirements.

The target markets can be divided into up/mid/downstream, which includes onshore and offshore/subsea plants, oil & gas pipelines, refineries, and power generation such as nuclear and thermal power plants. The company manages the whole cycle of production, distribution and after-sales services in all these markets. EPC companies represent the largest part of its capacity. Close co-operation with clients gives the company the opportunity to develop the market and the products in line with trends in the field of energy.

Standard Fittings

Elbows Up to 120″ All Grades Seamless and welded (cold formed, hot formed and by mandrel)

Equal And Reducing Tees Up to 120″ All Grades Seamless and welded (cold formed and hot formed)

Concentric and Eccentric Reducers Up to 120″ All Grades Seamless and welded (cold formed and hot formed)

Caps Up to 120″ All Grades Seamless (cold formed and hot formed)

Special Fittings

Reducing elbows Up to 60″ All Grades Seamless and welded

Special radius bends (3D) Up to 56″ All Grades Seamless and welded segmentable

Special radius bends (2,5D 3D 4D 5D 7D 1OD 18D) Up to 60″ All Grades Seamless and welded (hot induction and cold formed)

Barred tees Up to 120″ All Grades Seamless and welded (cold formed and hot formed)

Special flow tees Up to 120″ All Grades Seamless and welded

Equal and reducing crosses Up to 120″ All Grades Seamless and welded

Equal and reducing laterals Up to 120″ All Grades Seamless and welded

Special Products

Headers and extruded manifolds Up to 120″ All Grades Seamless and welded

Split tees Up to 120″ All Grades Seamless and welded segmentable

“Y” pieces Up to 120″ All Grades Seamless and welded (hot induction and cold formed)

Special Products as per customer drawings.

Materials used and related International Standards

Design Codes Manufacturing Standards

ASME B31.1 -ASME B31.3 ASME B16.9-ASME B16.25

ASME B31.4-ASME B31.8 MSS-SP43 – MSS-SP75

EN 13445 – 13480 – 12952 (former BS PD 5500 Swedish ordinance AFS 1994:39 ) DIN 2605 – 2606 – 2615 2616 – 2617 – BS 1640

DIN 2413 – TRD301 GOST 17374 – 17375 17376 – 17377 – 17378 17379 – 17380

AD 2000 Merkblatt B2-B3-B9 EN 10253

STOOMWEZEN rules for pressure vessels ISO 15590

MSS- SP-75 BS/EN 14870

CARBON AND ALLOY STEEL FOR ROOM, MODERATE AND ELEVATED TEMPERATURES STAINLESS STEEL HIGH YIELD STEEL FOR PIPELINE AND OFFSHORE CARBON AND ALLOY STEEL FOR LOW TEMPERATURE SERVICE AUSTENITIC/FERRITIC STAINLESS STEEL COPPER ALLOY NICKEL ALLOY TITANIUM ALLOY

ASTM / ASME A/SA 106 ASTM / ASME A/SA 312: TP304 -TP304L -TP304H TP304LN -TP304N TP316-TP316L-TP316H TP316LN -TP316N -TP317 TP317L -TP321 H -TP347 TP347H – S31254 and equivalent grades API 5L: Gr. X42 – X46 – X52 X60 – X65 – X70 – X80 ASTM / ASME A/SA 333: Gr. 6, Gr. 3, Gr. 8 and equivalent grades ASTM / ASME A/SA 790: UNS 31803 (duplex) – UNS 32750 (superduplex) UNS 32760 (superduplex) UNS 32550(superduplex) and equivalent grades Copper-nickel ASTM /ASME B/SB 466: UNS C70600 (Cu Ni 90/10) UNS C71500 (CuNi 70/30) and equivalent grades. ASTM / ASME B/SB 366: UNS N04400 – UNS N06600 UNS N06625 – UNS N08020 UNS N08800 – UNS N08811 UNS N08825 – UNS N10276 and equivalent grades. ASTM / ASME B/SB363: WPT2-WPT12 and equivalent

ASTM / ASME A/SA 106 ASTM / ASME A/SA 403: WP304 -WP304L -WP304H WP304LN -WP304N WP316 -WP316L-WP316H WP316LN -WP316N WP317 -WP317L -WP321 WP321 H -WP347 WP347H -WPS31254 EN 10208-2: L245NB L290NB – L360NB – L415NB L360QB – L415QB – L450QB L485QB – L555QB – L360MB L415MB – L450MB L485MB and equivalent grades. ASTM / ASME A/SA 420 WPL6 -WPL3 ASTM / ASME A/SA 815: UNS 31803 (duplex)

ASTM / ASME A/SA 335: Gr.1 – Gr.11 – Gr.12 – Gr.5 Gr.22 – Gr.9 – Gr.91 RCC-M: CL 1 – CL2 – CL3 grades Z2CND17.12 Z2CN18.10 – Z2CND18.12N (other grades can be supplied upon request) ASTM A860/MSS-SP75: WPHY 42 WPHY 46 -WPHY 52 -WPHY 60 -WPHY 65 WPHY 70 grades-WPHY 80 only as per MSS-SP75

ASTM / ASME A234: WPB WPC-WP1 -WP11 -WP12 WPS -WP22 -WP9 -WP91 WP92 ASTM A774: TP304L TP316L TP317L -TP321 TP347

EN 10216-2: P195GH P235GH – P265GH 20MnNb6 – 16Mo3 – 8MoB5 4- 14MoV63 1 0CrMoS-5 – 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4 X11 CrMo5 – X11 CrMo9-1 X1 0CrMoVNb9-1 X1 0CrWMoVNb9-2 X20CrMoV11-1 and equivalent grades Equivalent grades of EN 10253-3 EN 10253-4 (former AFNOR-DIN-BS equivalent grades).

EN 10253-1 EN 10253-2 RCC-M: CL2 – CL3 – NC grades P265GH – P280GH P295GH – P355NH -TU42C AE250B1 (other grades can be supplied upon request).

Product Structure

Standard Specication For Buttweld Equal Tee

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/2″NB TO 48″NB IN

Type : Seamless / ERW / Welded / Fabricated

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and

etc.

Form : Equal Tee, Pipe Tee, Butt weld Tee, Barred Tee, Lateral Tee.

Material & Grades of Buttweld Equal Tee :

Stainless Steel Buttweld Equal Tee :

ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DIN

1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Duplex & Super Duplex Steel Buttweld Equal Tee :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werksto No. 1.4462

Carbon Steel Buttweld Equal Tee :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Buttweld Equal Tee : ASTM A420 WPL3, A420 WPL6

Alloy Steel Buttweld Equal Tee :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Buttweld Equal Tee :

ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No.

N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel

600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No.

N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe

ASME B16.9 Buttweld Equal Tees Available Types

| Buttweld Equal Tee | Butt Weld Tees |

| ASME B16.9 Butt weld Equal Tee | Steel Tee Pipe Fittings |

| Stainless Steel Equal Tee | Suppliers SS Equal Tees |

| ANSI B16.9 Buttweld Tee Dealer | ASME B16.28 Buttweld Pipe Tees Exporter |

| Welded Butt weld Equal Tee Stockholder | Seamless Butt weld Equal Tee Distributors |

| Carbon Steel Lateral Tee | High Quality Equal Tee Manufacturer |

| ASTM A403 Stainless Steel Equal Tees | Duplex Steel Buttweld Tee |

| Super Duplex Steel Buttweld Tee | Copper Nickel Equal Tee |

| High Nickel Alloy Equal Tee | Hastelloy Pipe Tees Stockist |

| Titanium Buttweld Tee | Inconel Butt weld Barred Tee |

Buttweld Equal Tees Application

ASME B16.9 Equal Tee is known to deliver exceptional performance and are generally developed for meeting

the demands. We offer a broad range of Buttweld Pipe Tee through a worldwide network of stock-keeping

branches. These Equal Pipe Tees is used in various industries like :

Stainless Steel Buttweld Equal Tee uses in Oil and Gas Pipeline

Butt weld Equal Tees uses in Chemical Industry

Alloy Steel Equal Tee uses in Plumbing

Buttweld Pipe Tee uses in Heating

Buttweld Equal Tee Fittings uses in Water Supply Systems

ANSI B16.9 Buttweld Equal Tee uses in Power Plant

Buttweld Equal Tee Fitting uses in Paper & Pulp Industry

Equal Tee uses in General Purpose Applications

Buttweld Tees uses in Fabrication Industry

Equal Tee uses in Food Processing Industry

Buttweld Equal Tee uses in Structural Pipe

Technical Parameters

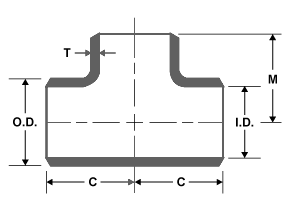

Carbon Steel Pipe Fitting – Straight TEE

| Nominal | Outside | Inside | Wall | Center | Center | Pipe | Weight |

| Pipe Size | Diameter | Diameter | Thickness T | To End C | To End M | Schedule | Pounds |

| 1/2 | 0.84 | 0.622 | 0.109 | 1 | 1 | 40 | 0.35 |

| 3/4 | 1.05 | 0.824 | 0.113 | 1.12 | 1.12 | 40 | 0.5 |

| 1 | 1.32 | 1.049 | 0.133 | 1.5 | 1.5 | 40 | 0.75 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.88 | 1.88 | 40 | 1.3 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 2.25 | 2.25 | 40 | 1.9 |

| 2 | 2.38 | 2.067 | 0.154 | 2.5 | 2.5 | 40 | 3.2 |

| 2 1/2 | 2.88 | 2.469 | 0.203 | 3 | 3 | 40 | 5.8 |

| 3 | 3.5 | 3.068 | 0.216 | 3.38 | 3.38 | 40 | 7.2 |

| 3 1/2 | 4 | 3.548 | 0.226 | 3.75 | 3.75 | 40 | 9.5 |

| 4 | 4.5 | 4.026 | 0.237 | 4.12 | 4.12 | 40 | 12.7 |

| 5 | 5.56 | 5.047 | 0.258 | 4.88 | 4.88 | 40 | 20.8 |

| 6 | 6.62 | 6.065 | 0.28 | 5.62 | 5.62 | 40 | 33.1 |

| 8 | 8.62 | 7.981 | 0.322 | 7 | 7 | 40 | 56.5 |

| 10 | 10.75 | 10.02 | 0.365 | 8.5 | 8.5 | 40 | 90.9 |

| 12 | 12.75 | 12 | 0.375 | 10 | 10 | * | 136 |

| 14 | 14 | 13.25 | 0.375 | 11 | 11 | 30 | 162 |

| 16 | 16 | 15.25 | 0.375 | 12 | 12 | 30 | 206 |

| 18 | 18 | 17.25 | 0.375 | 13.5 | 13.5 | * | 272 |

| 20 | 20 | 19.25 | 0.375 | 15 | 15 | 20 | 350 |

| 24 | 24 | 23.25 | 0.375 | 17 | 17 | 20 | 508 |

| 30 | 30 | 29.24 | 0.38 | 22 | 22 | * | 835 |

| 36 | 36 | 35.24 | 0.38 | 26.5 | 26.5 | * | 1,294 |

| 42 | 42 | 41.24 | 0.38 | 30 | 28 | * | 1,495 |

| 48 | 48 | 47.24 | 0.38 | 35 | 33 | * | 2,300 |

Reviews

There are no reviews yet.